Industrial Infrared Wall-Heaters have been gaining popularity in the industrial sector due to their efficiency in heat distribution. These innovative heating systems are revolutionising how industrial spaces are heated, providing a cost-effective and environmentally friendly solution for businesses. Industrial infrared heating systems are paving the way for a more sustainable future in the industrial heating industry.

Understanding Industrial Wall Heaters

Industrial Wall Heaters utilise a distinct method of heat distribution, setting them apart from conventional heating systems. These innovative devices emit infrared radiation, which directly warms objects, surfaces, and people within its range, rather than relying on heating the surrounding air. This direct approach to heating ensures a more efficient transfer of energy, leading to quicker warmth in industrial environments.

Unlike traditional methods, which often lead to significant energy wastage through air circulation and loss, Wall Heaters offer a targeted solution. These heaters significantly reduce energy consumption by heating only the required areas without dispersing warmth into unoccupied spaces or losing it through ventilation.

This method enhances the comfort levels within industrial settings and aligns with the growing need for energy conservation and efficiency in operations. Infrared technology in these heaters embodies a sophisticated yet practical solution to the challenges of heating large, open, or poorly insulated industrial spaces, demonstrating a marked shift towards more sustainable and cost-effective heating solutions in the industrial sector.

The Advantages of Industrial Infrared Heating Panels

The Advantages of Industrial Infrared Heating Panels

Efficient Heating for Industrial Spaces

Infrared Heating Panels provide an efficient solution for heating vast and complex industrial spaces. Their unique ability to emit infrared radiation ensures that warmth is distributed directly to surfaces, objects, and individuals, bypassing the need to warm the air first. This method results in an immediate feeling of warmth, improving comfort levels in the workplace with remarkable efficiency.

Energy-Saving Properties

These heating panels are renowned for their energy-saving properties. By focusing the heat directly where it is needed, they significantly reduce the amount of wasted energy, contributing to lower operational costs. This makes Industrial Infrared Heating Panels an economically advantageous choice for businesses aiming to optimise their energy usage.

Space-Saving Design

Due to their design, Infrared Heating Panels can seamlessly integrate into any industrial environment without taking up valuable space. Their slim profile and aesthetic versatility do not interfere with the workspace’s functionality or design, allowing for a harmonious blend with the industrial setting.

Improved Air Quality

The direct heating method employed by these panels helps maintain healthier air quality on industrial premises. Unlike conventional heaters, they do not circulate dust and other airborne particles, offering employees a cleaner and more comfortable working environment.

Minimal Maintenance

Infrared Heating Panels require minimal maintenance, a significant advantage for busy industrial settings. Their durability and the absence of moving parts mean these systems are less prone to breakdowns and wear, ensuring a longer service life and reducing maintenance costs.

Why are infrared wall-heaters the Future of Industrial Heating?

Infrared Wall-Heaters are increasingly recognised as the avant-garde of industrial heating, thanks to their sophisticated approach to delivering warmth directly to objects and individuals within a space. This method signifies a shift from conventional heating systems, often resulting in energy inefficiency due to heat loss in circulation and ventilation. The inherent ability of these heaters to provide immediate heating upon activation revolutionises the working environment for industrial setups by ensuring spaces are warmed promptly, thereby enhancing the comfort and productivity of the workforce.

Furthermore, the role of Infrared Wall-Heaters in promoting environmental sustainability cannot be overstated. By significantly reducing energy consumption, these systems align with global efforts to decrease carbon footprints and combat climate change. The practicality of Infrared Wall-Heaters extends beyond their environmental benefits; their design allows for seamless integration into various industrial environments, making them a versatile solution to heating needs. The future of industrial heating undeniably leans towards these innovative systems, as they offer compelling advantages over traditional heating methods, setting a new standard for efficiency, sustainability, and workplace well-being in the industrial sector.

Industrial Infrared-Heating Panels: Cutting-Edge Solutions for Heat Distribution

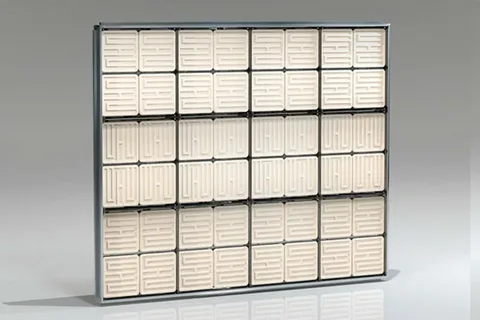

Industrial Infrared-Heating Panels represent the forefront of innovation in heat distribution within the industrial sphere. These panels are ingeniously designed to cater to the specific demands of vast and complex industrial spaces, delivering warmth directly to surfaces, objects, and individuals. Their unique mechanism of action sets them apart, as they do not heat the air but rather use infrared radiation to warm the intended targets directly. This method of heating ensures an efficient and even distribution of warmth, eliminating cold spots and creating a more uniform temperature across the workspace.

The technology behind these panels is efficient and adaptable, allowing for installation in various settings, including areas with high ceilings or open spaces where traditional heating solutions would falter. Furthermore, their sleek and discreet design does not compromise the aesthetic or functional use of the space, offering a heating solution that is both effective and visually appealing. The strategic implementation of these panels can significantly enhance the thermal comfort of an industrial environment, making them an indispensable tool in the pursuit of an optimised heating system.

Installation Considerations for Industrial Infrared-Heating Systems

When considering the installation of Industrial Infrared-Heating Systems, several key factors must be considered to ensure optimal functionality and efficiency. The spatial layout plays a crucial role; the configuration of the industrial environment will influence the positioning and number of infrared panels needed to achieve uniform heat distribution. It is equally important to determine the appropriate mounting height for the panels, which varies based on the specific application and size of the room. High ceilings require panels to be mounted at greater heights to effectively reach work areas, while lower ceilings can benefit from a different approach to avoid overheating or discomfort.

Additionally, potential obstacles that could hinder the direct line of infrared radiation—such as large machinery or structural columns—must be carefully considered. These barriers can block the infrared waves, creating cold spots and reducing the system’s overall efficiency. Strategically placing the panels to circumvent these obstacles can significantly enhance the effectiveness of the heat distribution.

Before finalising the installation plan, it is advisable to consult with professionals experienced in implementing Industrial Infrared-Heating Systems. Their expertise can guide the optimal setup, ensuring that the system meets the specific heating requirements of the industrial setting without compromising on energy efficiency or performance.

Maximise Efficiency with the Best Infrared Heater for Your Industrial Needs

To maximise efficiency in an industrial setting, selecting the best infrared heater tailored to specific requirements is crucial. Factors such as the size of the space, ceiling height, and any obstacles that may impede infrared radiation play pivotal roles in determining the most suitable heater.

The best-infrared heaters are designed to offer optimal performance, integrating seamlessly into the industrial environment without sacrificing space or aesthetics. They are equipped with features that enable precise control over temperature settings, allowing for customised heating schedules that match the facility’s operational hours, thereby reducing energy wastage.

Additionally, top-tier models are constructed with durable materials, ensuring they withstand the rigours of industrial use while maintaining high levels of efficiency over time. By prioritising these aspects when selecting an infrared heater, businesses can balance maintaining a comfortable working environment and optimising energy consumption, ultimately contributing to both operational savings and environmental sustainability.

The Environmental Benefits of Switching to Infrared

Adopting Industrial Infrared-Heating Systems is pivotal in promoting environmental sustainability within the industrial sector. These systems distinguish themselves through superior energy efficiency, directly translating into a reduction of greenhouse gas emissions. Such a shift is instrumental in helping businesses diminish their ecological footprint and aligning with global initiatives aimed at climate change mitigation.

The intrinsic efficiency of Infrared Wall-Heaters ensures that energy consumption is kept to a minimum, thereby not only conserving valuable resources but also contributing to a significant decrease in the emission of pollutants. This move towards Infrared technology marks a conscientious step towards fostering a greener, more sustainable industrial environment, highlighting the responsibility of the sector to lead by example in environmental stewardship.

Cost-Benefit Analysis of Infrared Wall Heaters

The financial implications of adopting industrial infrared-heating systems form a crucial consideration for businesses when evaluating heating solutions. The initial outlay for these heaters often surpasses that of conventional systems; however, this is counterbalanced by notable reductions in operational costs.

Infrared wall heaters technology directly transfers heat to objects and individuals, eliminating the inefficiencies associated with heating air and the consequent energy wastage. This direct method of heating not only accelerates the warming process but also significantly curtails energy consumption. Over time, the savings from lower energy bills and the minimal maintenance requirements inherent to Industrial Infrared-Heating Panels substantiate the initial investment.

Furthermore, the durability of these systems extends their lifespan, further enhancing the cost-effectiveness of the investment. Organisations that transition to infrared heating witness a tangible decrease in heating expenses, underscoring the economic viability of these systems in the industrial sector. This analysis underscores the rationale behind the growing preference for Industrial Infrared-Heating Systems as a financially sound and efficient heating solution.

Maintenance Tips for Infrared Heating Panels

Maintaining Industrial Infrared-Heating Panels in optimal condition is crucial for prolonging their service life and ensuring consistent efficiency. Regular dusting and cleaning of the panel surfaces are imperative to prevent any build-up of dirt or debris that might impede infrared radiation.

This simple yet effective routine helps maintain the panel’s ability to deliver direct warmth effectively. Additionally, a periodic inspection of the electrical components is recommended to identify any potential issues early, preventing downtime or costly repairs. It’s also advisable to check the panels for any signs of wear or damage, such as cracks or discolouration, which could affect performance.

Adhering to these maintenance practices supports the smooth operation of the heating system, creating a comfortable and productive industrial environment. Implementing a scheduled maintenance plan can aid in identifying minor issues before they escalate into significant problems, ensuring the panels continue functioning as intended.

Conclusion

The advent of Industrial Infrared Heating Systems represents a transformative leap forward in the approach to efficient heating within the industrial sector. With their innovative design and operation, these systems stand at the forefront of energy efficiency, operational cost reduction, and environmental stewardship. The investment in Infrared Wall-Heaters signifies a shift towards a more sustainable, cost-effective, and comfortable working environment. As the industrial world continues to seek solutions that align with economic and ecological objectives, these heating systems underscore the critical role of advanced technology in achieving these goals. Their adoption elevates workplace comfort and productivity standards and marks a commitment to a greener and more sustainable future.

FAQs

1. How do Infrared Wall Heaters compare to traditional heating systems in industrial environments?

Infrared Wall Heaters provide a direct heating method, focusing warmth on objects, surfaces, and people rather than heating the air. This approach minimises energy wastage and enhances efficiency, setting them apart from traditional systems that rely on circulating heated air.

2. What factors should be considered when choosing the Best Infrared Heater for an industrial setting?

Selecting the best infrared heater involves assessing the spatial dimensions, ceiling height, and the presence of potential obstructions that could affect infrared radiation. Efficiency, durability and the capacity to integrate with existing workspace layouts are crucial considerations.

3. Can Industrial Infrared Heating Systems be used in all industrial spaces?

These systems are versatile. Thanks to their flexible installation options and scalable design, they can be adapted to various environments, including large open spaces, areas with high ceilings, or zones requiring targeted heating.

4. Are there significant energy savings associated with installing Industrial Infrared Heating Panels?

By directing heat precisely where it’s needed and reducing energy wastage, Industrial infrared heating panels can contribute to substantial operational cost savings over time.

5. What maintenance is required for Industrial Infrared Heating Systems?

These systems are relatively low-maintenance, requiring only regular cleaning of the panels to prevent dust accumulation and occasional checks of the electrical components to ensure optimal performance.

| Other Good Articles to Read |

| skank blogs |

| unreal blogs |

| tba blogs |

| all city forums |

| dany blogs |

| the music blogs |

| key forums |

| the big blog theory |

| joe blogs |

| blogs 4 me |

| Blogs Emon |

| Related Business Listings |

| Contact Directory |

| Local Business Profiles |